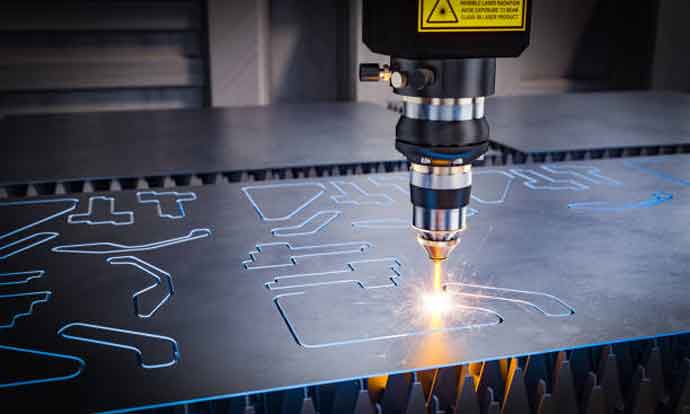

If you’re considering purchasing a CNC machine, you have many choices. Consider your budget, experience, power consumption, and material selection. In this article, we’ll go over how to find the right machine for your needs. Keep reading for more tips on CNC machine selection. A CNC machine can be the perfect tool for your business. The right machine will allow you to complete your job quickly and easily. There are many benefits to CNC machines, but not all of them will be right for your needs.

Power consumption

CNC machines are energy-hungry pieces of equipment. They often require three-phase power. As such, building owners must ensure that they can provide sufficient power for their new equipment. To ensure that you have enough power in your building, you should find out how much power you currently use. The addition of a CNC machine to your shop may push its power consumption beyond what is currently available. To avoid this, be sure to check how much power is available before buying your CNC.

Feed rate

Among the most important factors to look at when picking a CNC machine is the feed rate. A CNC machine’s feed rate is directly related to the material that it will be cutting. Whether it is steel, PCD diamond, or solid carbide, different machines have different feed rates. The diameter of the cutting bit will also affect its feed rate. Aluminum and plastic tooling cannot be re-sharpened and are generally not well-maintained. In addition, all the bits are different in their tips.

Material selection

If you are planning to use CNC machine for your industrial manufacturing, you must consider material selection. There are many factors to consider, including its strength, durability and cost. Consider your needs and prioritize your priorities. Here are some of the factors to consider.

Experience

One important aspect to consider when picking the right CNC machine supplier is customer support. A CNC supplier should be willing to answer questions, exchange suggestions, and provide technical support. Experienced CNC machine shops will usually seek references from other business associates, and you can also find customer reviews on websites. If possible, try to speak with the machine manufacturer and ask about the level of support they received. This way, you can ensure that you’re dealing with a reputable company that puts its customers first.

Reliability

The number one consideration in picking a CNC machine is reliability. This factor is critical when dealing with products that are complex electrohydraulics. This is because simple life distributions do not accurately reflect the true laws of reliability for complex systems. The Weibull model of machine reliability is a flexible, robust model that inherits the hierarchical structure of ANNs. It consists of three layers: input, hidden layer, and output layer.